Note: This website was automatically translated, so some terms or nuances may not be completely accurate.

Why a Cardboard Company Bought Dentsu Inc.'s "Bill Holder"

Masahiko Nohara

Tachibana Industries Co., Ltd.

Yuko Katsumata

Dentsu Inc.

As the first initiative in Dentsu Inc.'s " Intellectual Property Monetization " project, the cardboard-made simple household shrine "ofudana" was released by Tachibana Industries.

■Product Name: "ofudana" ■Price: ¥1,150 (tax included) ■Manufacturer/Distributor: Tachibana Industries

*Link to Amazon product page: From left ■Purple■Red ■LightBlue

Tachibana Industries President Masahiko Nohara, who commercialized the product under a design and trademark license from Dentsu Inc., and Dentsu Inc.'s Yuko Katsumata, the creator of ofudana, discuss the potential of new business models from their respective perspectives in manufacturing and advertising.

What challenges did the cardboard company and the advertising agency each face?

Masahiko Nohara, President, Tachibana Industries; Yuko Katsumata, Dentsu Inc. 2CRP Bureau

Katsumata: The origin of the ofudana product was Dentsu Inc.'s internal cross-departmental project, "Product Design School 2017." Dentsu Inc.'s art directors, planners, and copywriters used cardboard as a material to create product designs. The resulting collection of works was exhibited in the entrance of Dentsu Inc.'s headquarters last November and December.

Mr . Nohara saw the article introducing that exhibition in Web Dentsu Inc. News and took notice of the ofudana I designed. That led to Tachibana Industries commercializing it.

Nohara: Seven months from that meeting to the launch—it flew by! For Web Dentsu Inc . News readers, Tachibana Sangyo primarily manufactures and sells paper and plastic corrugated cardboard. They also handle all aspects of packaging related to corrugated cardboard, including cushioning materials and seals.

Katsumata:Founded in 1964, Tachibana Industries has over 50 years of history, but recently its business scope has been expanding.

Nohara: Since I became president about ten years ago, we've been focusing on "logistics processing." We've now acquired a specialized food factory where we handle packaging and assembly for items like cookies and chocolates, as well as manufacturing and selling tea bags.

Katsumata: It's unusual for a cardboard manufacturer to handle food products, isn't it? What prompted you to venture into products beyond packaging?

Nohara: For consumers, cardboard is essentially the same regardless of the manufacturer. In fact, it's a product where inconsistency leads to complaints, making differentiation and adding value challenging.

As a consumable, orders themselves are relatively steady. But in that environment, we easily get caught in price competition. With changing consumer purchasing behavior and rising raw material costs today, how to create added value became a major challenge.

Katsumata: So why did you focus on food packaging?

Nohara: Because it leverages our core business expertise: our cardboard and packing technology and equipment. We established a successful business model by adding "setup work" to our traditional "box-only" sales model, enabling customers to purchase finished products with contents already packed inside.

Dentsu Inc., as an advertising agency, has also recently ventured into "product design licensing business." Was there a specific challenge driving this?

Katsumata: When I joined Dentsu Inc., it was a fully established advertising agency model centered on media transactions. However, as consumer behavior changed and client demands diversified, we knew we had to evolve. The challenge was finding ways to develop new businesses that weren't bound by past methods, while still leveraging the strengths of an advertising agency.

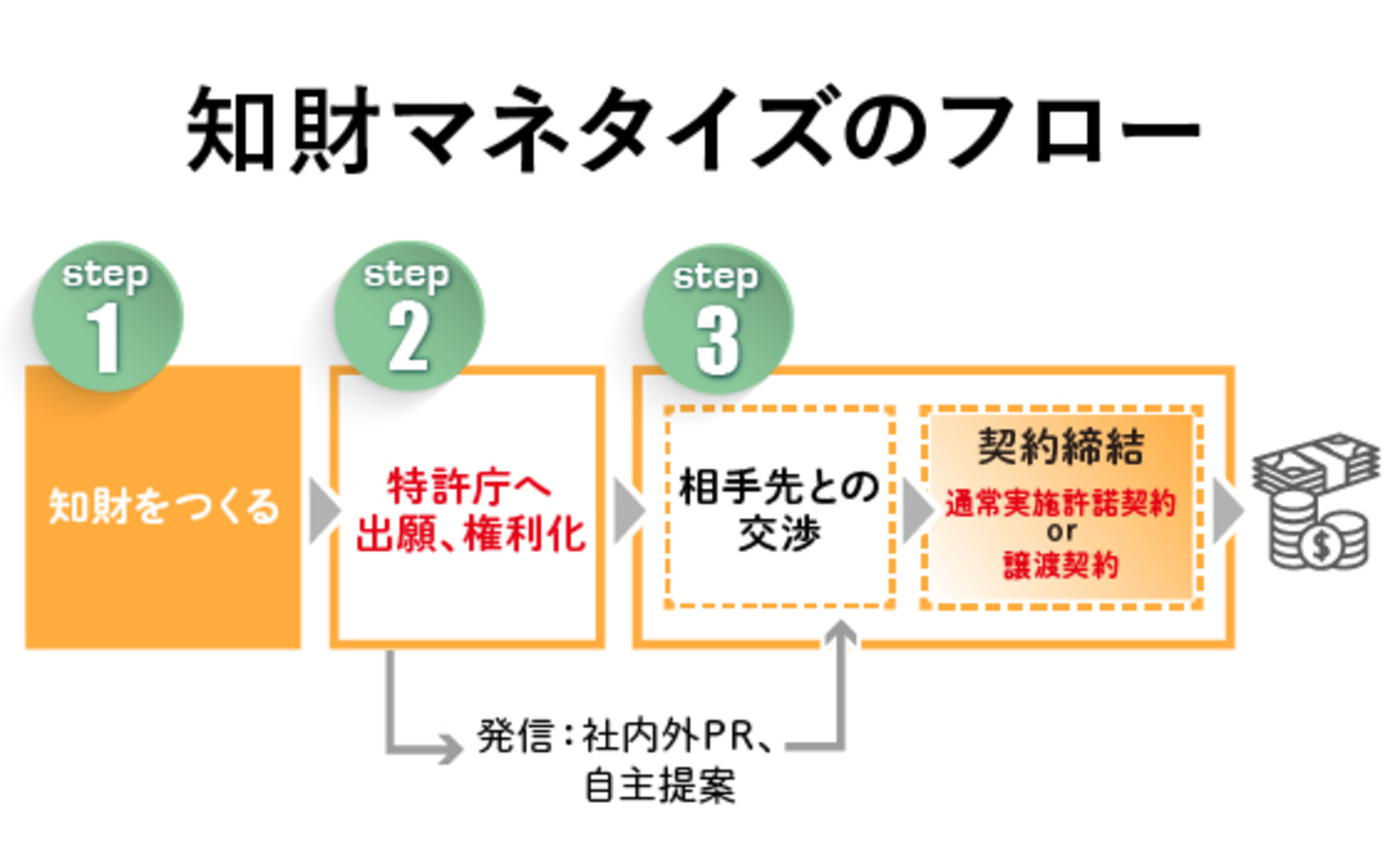

One such "new business leveraging the strengths of an advertising agency" is intellectual property monetization, utilizing design rights and trademarks for products.

Nohara: I see. In terms of business development, we also took the opportunity of our 50th anniversary to create our own brand of original tea bags, challenging ourselves in a "B to C" business. This leveraged the tea manufacturing know-how we cultivated through OEM production for other brands and the existing equipment we had in place.

This tea sold well online, and while we were thinking, "Can't we create more B2C products that leverage this sales channel?", we encountered ofudana.

A product focused on the value of "use and dispose"

Katsumata: As cardboard experts, what was your impression when Tachibana Industries saw the exhibits at Dentsu Inc.'s "Product Design School 2017"?

Nohara: It was shocking in a good way. We were always thinking about added value and differentiation, wanting to develop our own products unique to a cardboard company, but we lacked concrete ideas. That exhibition was full of hints for what we vaguely thought: "Cardboard should be capable of so much more."

Above all, it was striking to see cardboard—the "raw material for boxes"—being designed as a material for everyday household goods. It really hit home how our thinking and perspective had been stuck starting from "packaging materials."

Katsumata: Among all the products on display, why did you choose ofudana for commercialization?

Nohara: With ofudana, right after thinking "That's interesting," the blueprint immediately popped into my head (laughs). First, I saw it as mass-producible. But simply making it by machine wouldn't be interesting. With ofudana, I felt we could incorporate our expertise as a manufacturer.

Also, coincidentally, I'd just heard that wooden talisman stands were selling well at souvenir shops in Asakusa, where our office is located. That really sparked my interest! But how did you come up with the idea of a cardboard talisman stand?

Katsumata: Cardboard gets thrown away once its purpose is served, right? I first thought about how we could increase the value of cardboard itself—this "use it and throw it away" nature.

Then, when I was identifying small problems in my own life, the shrine talismans caught my eye. I buy talismans every time I visit a shrine, but since I don't have a household shrine altar, I always felt uneasy about just leaving them on my bookshelf. That's when I realized, "Oh, right, talismans are supposed to be returned to the shrine once a year for burning." If we made the talisman holder out of cardboard, it could be returned to the shrine along with the talisman at the end of its one-year cycle.

Nohara: So it was an idea born from your own life. And you thought there must be others with the same need.

Katsumata: Magazines regularly feature specials on shrine visits, and for many Japanese people, shrines and ofuda are very important. But, as was the case for me, depending on housing circumstances, setting up a household shrine can be a bit of a hurdle. I think it would be wonderful if ofudana could convey the lifestyle of having a household shrine, which is part of Japanese culture, in a different form.

President Nohara, what vision do you have for ofudana's product development?

Nohara: I think there are many possibilities. I'm particularly intrigued by the potential for diverse sales channels, like souvenir shops along the approach to Sensoji Temple or Buddhist altar goods stores. How did you envision people purchasing them, Ms. Katsumata?

Katsumata: Ideally, it would be best if a shrine maiden handed it to you when you bought an ofuda at the shrine! I want it to reach people who want to enshrine an ofuda but don't have a kamidana at home. Also, since it turned out so cute, I'd be happy if it became something that naturally fits into daily life as interior decor. Its true purpose is as an ofuda stand, but it could also work as a card holder for temporarily storing incoming mail, right?

Nohara: That's true. We didn't realize it during the design and prototyping stages, but seeing the finished product, it looks like it could work well displaying shop cards in restaurants too.

Katsumata: I think cardboard's inherent "disposable" nature allows us to create value that "eases the pressure of buying things or feeling obligated to use them forever." Not just ofudana, but many product ideas in the "Product Design School" exhibition focused on this characteristic.

Nohara: I was immediately drawn to ofudana's design quality, but I imagine reaching this final shape involved a lot of effort?

Katsumata: Creating the blueprints was tough. My usual work involves graphic design, so my mind operates primarily in two dimensions. But to secure the design patent, I had to draw extremely precise blueprints...

Nohara: It seemed like everyone else struggled with three-dimensional objects too. Some exhibits had edges that were stiff and rigid, which we found rather endearing (laughs).

Katsumata: How embarrassing (laughs). We'd cut and assemble according to the drawings, only for it to not stand properly. Then we'd go back to the drawings and start over... it was a constant cycle of trial and error. I suppose that's just part of product design work. The difference between what you envision in your head and what you can actually create with your hands was tough.

Cardboard has infinite possibilities!

Katsumata: You managed to get it to market in just seven months after the exhibition. How did you feel about the benefits of buying a product idea from an advertising agency and commercializing it?

Nohara: First, it was great to experience the development process of turning proposals and ideas from outside the cardboard industry into products, while effectively dividing the roles. Also, printing and processing cardboard often involves specific misalignments. It was rewarding and interesting to fully propose solutions for these processing techniques – our area of expertise.

It was a great stimulus for our employees too, so if opportunities like this arise again, we'd definitely like to take on the challenge! I believe the entire cardboard industry feels the same way.

Katsumata: I think we added value to a product that wasn't packaging this time. How do you see the potential for B2C products utilizing cardboard?

Nohara: Corrugated cardboard's advantages include small-lot production, short lead times, easy processing, and low initial costs. Plus, it's recyclable and allows for customized, multi-variety production. As a material, it's a top performer.

Seeing Dentsu Inc.'s ideas, starting with Mr. Katsumata's ofudana, I felt there are many areas where cardboard can shine. Unfortunately, ideas within the industry itself are hard to come by. Right now, the best shortcut to greatly expand possibilities might be to take ideas from outside the industry and develop collaborative products.

Katsumata: What struck me most while working with Tachibana Industries this time was how powerful it is to be able to make things immediately.

We usually turn ideas into business. We don't have our own factories, and we rarely work directly with manufacturers to create something. But collaborating with people who actually have factories and make things, I felt the strength of that speed – the power of being able to just make something and think about it, and see your ideas take shape immediately.

In that sense, we also see new potential in the form of a "product design licensing business."

Nohara: If ofudana sells well, it might motivate our employees to think, "Could our ideas become the next ofudana?" and inspire them to create something themselves. Seeing this, the cardboard industry might start thinking beyond just boxes, leveraging their materials, production techniques, and equipment to come up with new ideas. I hope this leads to the development of the entire industry.

Katsumata: We also hope ofudana's existence will be a stimulus within Dentsu Inc. It would be great if people realized, "Dentsu Inc. can do things like this," and it helped create an environment where people feel empowered to take on various challenges. Thank you very much for today!

Was this article helpful?

Newsletter registration is here

We select and publish important news every day

For inquiries about this article

Author

Masahiko Nohara

Tachibana Industries Co., Ltd.

President and CEO

Born in Tokyo. Graduated from Keio University's Faculty of Economics. After seven years at a major metropolitan bank, joined the company in 1997. As the second-generation head of a packaging manufacturer, became President and Representative Director in 2007. That same year, acquired a food factory and expanded into logistics and processing for food products (black tea, confectionery, gifts, etc.). Certified Tea Advisor by the Japan Tea Association.

Yuko Katsumata

Dentsu Inc.

Second CR Planning Bureau

Art Director

Born in Shizuoka Prefecture. Graduated from Tama Art University's Graphic Design Department. Joined the company in 2004. Handled numerous clients including food and beverage companies, airlines, and insurance companies. Performs art direction for all aspects of communication, including V.I., graphic design, and product packaging.