The "Don't Let It End PROJECT" is a social issue-focused upcycling platform that aims to reduce environmental impact through the "creative reuse" of items no longer used in corporate activities, while also promoting awareness and advancement of DEI (Diversity, Equity & Inclusion).

Since its launch in March 2022, it has proposed sustainable practices that even urban/non-manufacturing companies can easily adopt through two projects.

How does the "Don't Let It End PROJECT" contribute to solving challenges for companies and society? What insights have emerged through its activities? Ms. Mineko Hotta of Dentsu Inc., who drives this project, and Ms. Hiromi Ogasawara of DENTSU PROMOTION PLUS INC. explain.

Sustainable activities that urban/non-manufacturing companies can realistically maintain

Hotta: I'm Mineko Hotta from Dentsu Inc.'s Sustainability Consulting Office. We support companies in sustainable management and creating sustainable business.

The 'Don't Let It End PROJECT' is a social issue-focused upcycling program launched jointly by the Dentsu Inc. Japan Network and the domestic Dentsu Group. It aims to recycle plastic products no longer used in offices and other settings into new resources and pursue creative reuse.

In recent years, companies across all industries and sectors are being called upon to focus on ESG (Environmental, Social, and Governance). However, for urban-based, non-manufacturing companies, one challenge has been the limited opportunities to take action, particularly from the perspective of reducing environmental impact.

Thus, Dentsu Inc. —itself an urban, non-manufacturing company—became its own test subject, exploring mechanisms for continuous engagement within daily business operations. This marked the beginning of this project.

We focused on plastic products no longer used in the office, such as clear file folders, PET bottles for stored water (which are regularly replaced), and disaster helmets. We collect these items and upcycle them into new products with added value through creative ideas. To achieve this, we partnered with Pantec, a plastic recycling professional, to create a scheme where plastic products are crushed, mixed, and processed into recycled pellets.

Furthermore, they developed mechanisms to utilize the upcycled products for internal and external communication to raise awareness and promote DEI, as well as a system to circulate surplus recycled material within the domestic market instead of discarding it. They also created a menu of services to enable other companies to utilize this platform.

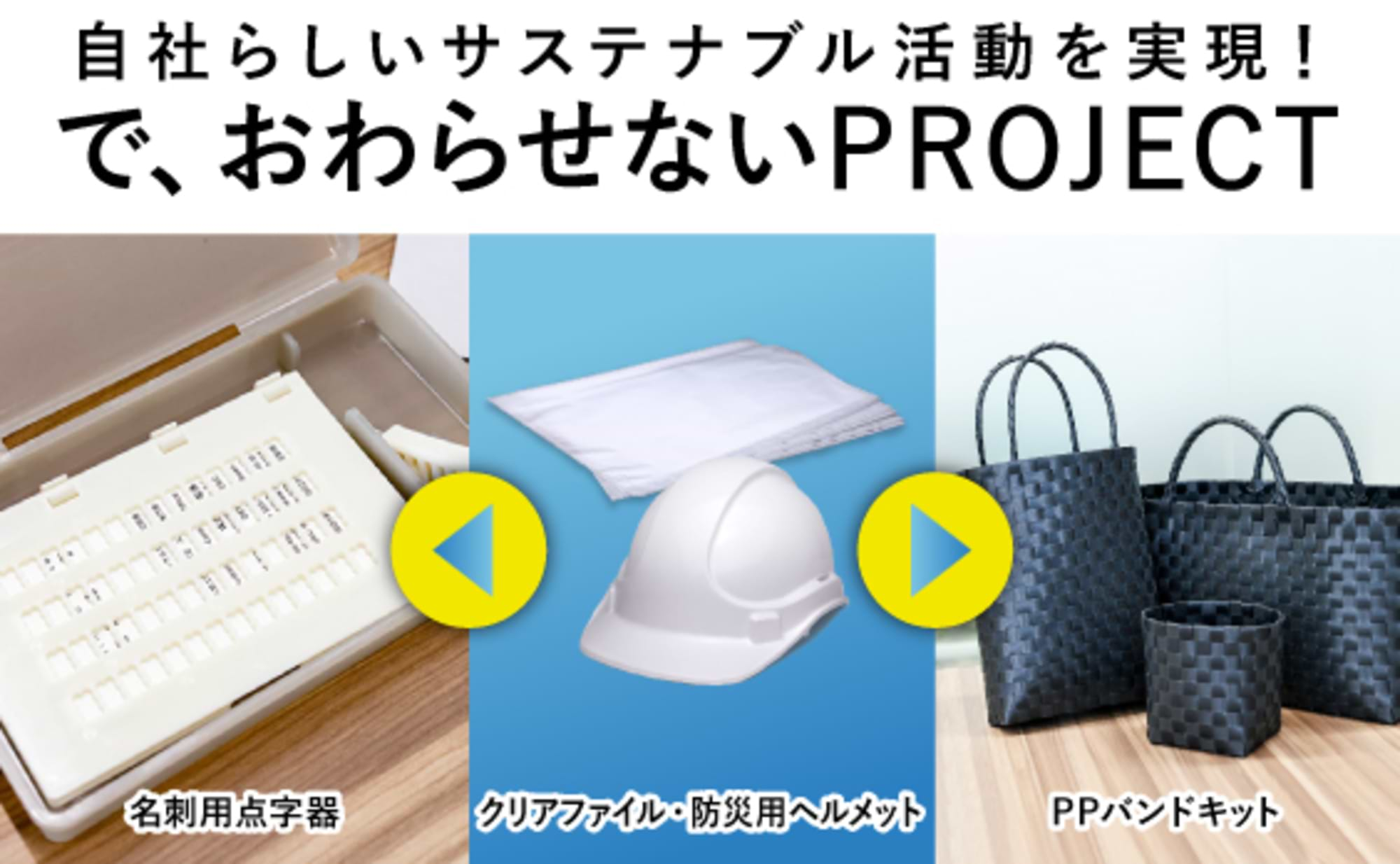

Starting with the "Braille Embosser for Business Cards," aiming to reduce environmental impact and contribute to DEI

Hotta: The first project we implemented was developing the "ten・ten (TenTen) Braille Embosser for Business Cards," which allows anyone to easily add Braille to their cards. We repurposed the embosser and stylus from disaster helmets nearing their replacement date, and created a dedicated case from unused clear files. We then held workshops for employees of the Dentsu Group in Japan on creating Braille business cards.

The key point of this initiative is designing activities that are accessible and easy for any employee to engage with. Simply telling people "Let's recycle" makes it hard for them to feel personally invested. However, when familiar office items like clear file folders and helmets are repurposed into tools that add braille to business cards—something used by many in offices and business settings—upcycling becomes a more relatable story.

Furthermore, the act of writing braille itself is part of a DEI experience, and participating in the workshop raises awareness of DEI. Using braille-included business cards during exchanges expands communication circles with external parties, fostering DEI awareness and promotion.

Furthermore, members of Dentsu Solari Inc., a subsidiary company aiming to promote and stabilize employment for people with disabilities, participate in collecting the clear files. This integration of a DEI perspective into the upcycling process itself is a key point.

Thus, the first project achieved both objectives: "reducing environmental impact" and "contributing to DEI," earning the 2022 Good Design Award. However, to ensure it wasn't a one-time effort, seven domestic Dentsu Group companies jointly initiated planning for the second project.

The product we arrived at through trial and error is the PP band kit "loop+loop". This kit allows users to create PP bands from collected clear files and assemble items like trash bins, PC cases, and bags. By engaging employees in handcrafting using this kit, we aim to provide the "experience" of actively participating in the circular loop.

As part of the Dentsu Group's volunteer promotion day "One Day for Change" (held globally in April 2023 with the theme "Circular Economy"), we invited 30 employees to participate in upcycling as one of the initiatives.

Furthermore, we wanted to challenge ourselves to employ people with disabilities for "ultra-short-term work" during the kit assembly (box packing) process. With the kit delivery deadline just one month away, we approached Mr. Ogasawara from DENTSU PROMOTION PLUS INC. HR, knowing it was a tall order.

Achieving the First "Ultra-Short-Term Employment" in the Domestic Dentsu Group

Ogasawara: From here, I, Ogasawara from DENTSU PROMOTION PLUS INC., will introduce the "ultra-short-term employment" initiative undertaken for the second project. Leveraging its expertise in planning, creative work, and production within the sales promotion field, the DENTSU PROMOTION PLUS INC. participated in this project from its planning and launch stages.

The "ultra-short-term employment" we challenged this time is a new employment model proposed by Professor Takeo Kondo of the University of Tokyo's Research Center for Advanced Science and Technology. It's an initiative to build a regional system that matches companies needing labor with job seekers wanting to work short hours (ultra-short-term workers), creating mutually beneficial employment.

The greatest challenge in introducing 'ultra-short-term employment' was that it was the 'first initiative of its kind within the Dentsu Group in Japan.' With no precedents, we had to examine and devise everything from scratch: the recruitment process, employment conditions, and salary payment methods. Furthermore, we had to complete the recruitment planning, internal approvals, and assembly execution within a short period of about one month until delivery. While the initiative's social significance in promoting DEI (Diversity, Equity, and Inclusion) ensured smooth internal approval, the subsequent operational phase became a full-scale project requiring the combined efforts of HR, Accounting, and the field teams.

We planned the recruitment numbers and work shifts based on a five-day assembly schedule for 1,000 workshop kits, following internal simulations. With strong support from our partners, Minato City and the certified NPO Minato Disability Welfare Organization, we rapidly conducted information sessions, casual interviews, and hiring screenings, successfully recruiting the planned number of people. Although one unexpected withdrawal occurred on the day, the team's performance exceeded our initial simulations, allowing us to successfully complete all tasks as scheduled.

Assembly work in progress.

One key lesson learned from the "ultra-short-term employment" initiative was the importance of accommodating disability characteristics in procedures and the work environment. For example, during the application process, contract support tailored to individual needs is essential. This includes having a representative present during contract signing. Small but crucial adjustments, like changing document font size and style for readability, and minimizing the number of fields the individual must fill out, are vital. Additionally, since some individuals struggle in quiet environments, we played music during the workday.

Before implementation, we were honestly uncertain about the level of demand for "ultra-short-term employment." However, we discovered it could meet the employment needs of individuals who, due to personal circumstances, find full-time work difficult and have previously lacked opportunities. This provided significant insight for considering future employment models.

We aim to build a social infrastructure platform utilized by diverse stakeholders

Adding ideas to objects to create new value while considering the environment. Furthermore, creating a system where everyone can participate to generate a better cycle. The "Don't Stop There PROJECT" has launched its third phase, aiming for further environmental impact reduction and contributions to DEI.

Finally, we asked Mr. Hotta and Mr. Ogasawara about their future outlook.

Hotta: I believe a key feature of the "Don't Stop There PROJECT" is that it doesn't just stop at making things; it designs the entire experience value and has a structure that makes it easy for various stakeholders to participate. Going forward, we plan to expand the types of plastics we handle, the forms of output, and the diversity of working styles. We want to develop it into a social infrastructure platform that can be utilized by various companies and organizations.

Ogasawara: Since our group is involved in many product manufacturing roles, we intend to actively explore applying employment styles that match the needs of people with disabilities, such as ultra-short-term employment for assembly work. Currently, companies have mandated disability employment rates under the Act on Employment Promotion of Persons with Disabilities. However, our ideal future is a society where such promotion frameworks become unnecessary, and anyone who wants to work can naturally find a place to do so. To ensure this initiative doesn't end here, we intend to continue our efforts in Diversity, Equity, and Inclusion (DEI).