The "Good JAPAN Innovation" project brings together exceptional Japanese craftsmanship and Dentsu Inc. art directors under the theme "Traditional Crafts × Design" to create collaborative works and share new value globally. The sixth installment focuses on traditional crafts from Okayama: "Denim." With the cooperation of Japan Blue Inc., a denim panda born from fabric has been created.

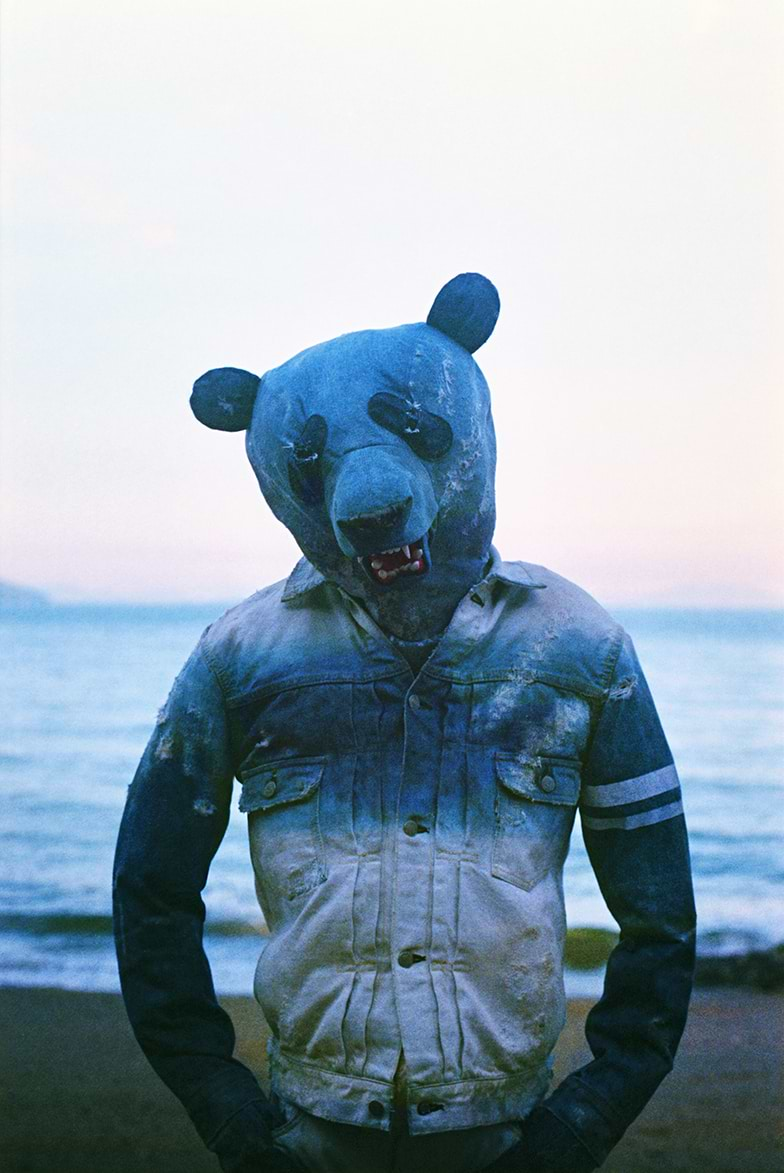

The completed Denim Panda

Okayama is famous for the Momotaro legend. What if Momotaro, who defeated the demons, had lived until modern times? What if Momotaro somehow transformed into a panda and wore jeans...?

I, Nakamura, came up with this idea and decided to consult Satoshi Teshirogi at Dentsu West Japan Inc. Okayama branch. Mr. Teshirogi said, "There's a brand called Momotaro Jeans in Kojima, so why don't we go together?" And so, off we went to Kojima, the birthplace of domestic jeans.

Kojima's Denim Culture

Long ago, Kojima in Kurashiki City developed its textile industry rooted in cotton cultivation. This area was once a major production hub for school uniforms. With abundant materials and high technical expertise, production shifted to jeans in the 1970s.

Although it suffered a major blow from the rise of fast fashion, it has recovered thanks to unique processing techniques and the uncompromising craftsmanship of its artisans. Today, it receives numerous offers from famous international brands.

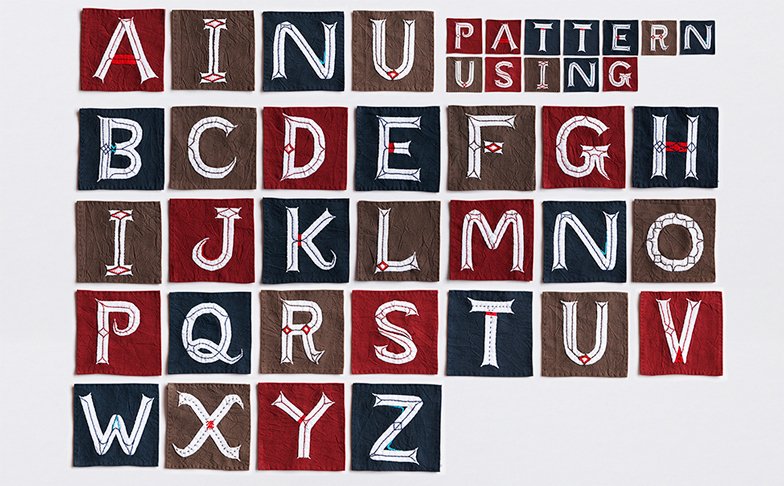

Japan Blue, who we asked to collaborate this time, is a central player in Kojima denim. They expand globally with denim that obsessively focuses on dyeing and weaving, starting with their own brand, "Momotaro Jeans."

Kojima Station, where denim enthusiasts are instantly recognized

The calm Seto Inland Sea, with the Seto Ohashi Bridge visible ahead

I wanted to create a panda that pursued realism

My first thought was that I absolutely didn't want it to be a cute mascot character. I envisioned creating a panda out of denim – one that was huge, eccentric, and would burn itself into your memory the moment you saw it. The motif, inspired by Okayama, is Momotaro.

From here, days of trial and error followed as we figured out how to bring it to life. First, based on my rough sketches, we held repeated meetings centered around Japan Blue's Kensaku Nagata to discuss the construction method.

Discussing the panda's size while looking at the actual product

Rough sketches drawn repeatedly to convey the image

We prepare fabric samples and carefully evaluate the colors and distressed effects

After discussion, we decided to create the parts as separate "face," "upper body," and "lower body" sections. For the face, we bought a bear stuffed animal, took it apart for reference, and created a pattern. Inside the denim, we stuffed it with Zimbabwe cotton, known for its flexibility and durability. The feel through the denim is just like human skin. But this adds significant weight.

To make it stand on its own, we bought a frame from a home improvement store, embedded it inside the denim, and then added cotton for body filler. Finally, we put gloves on its hands and shoes on its feet to complete it. As an aside, the sight of a man transporting a panda in his car on the morning commute from home to Okayama was undoubtedly police-reporting level.

Zimbabwe cotton boasts fewer fiber joints for strength, plus excellent sheen and softness.

Mr. Nagata of Japan Blue creating the hand section

Cover the frame with cotton to make it stand on its own. Since it's a panda, the belly area is white.

Everyone checks the overall look

Master craftsmen give the fabric character using various denim processing techniques

To make the new denim fabric look aged, various special treatments were applied to the panda fabric. Entering at this stage was Mr. Noriaki Nishiyama, a processing artisan from Mito. His skill in capturing the image we conveyed and executing it beyond expectations in one go was truly remarkable.

For instance, we recreated the demon's blood splatter on the face using aluminum paste processing, as we imagined the blood would be silver. To express battle scars, over 10 types of special processing were applied to the denim fabric: whiskering, shaving, distressing, crushing, bleaching, bio-washing, remake processing, spraying, and burner processing.

Denim processing artisan Mr. Nishiyama

Pursuing realism by applying processing to even the finest details

Demon's blood splatter applied with aluminum paste

Completion, and then to the shoot

Thus, the denim panda finished overnight the day before the shoot was photographed not on Oni Island, but on the remote island of Rokuguchi Island in Okayama. Early in the morning, we chartered a boat and headed to the natural monument "Elephant Rock," a bizarre rock formation resembling an elephant. This bizarre project—featuring a panda instead of Momotaro, and an elephant as the location—was successfully completed.

Making-of Movie

Planning Support & Denim Fabric Procurement: Katsuya Kimura, Kensaku Nagata, Hiromi Nishihara (Japan Blue)

Denim Fabric Processing: Norihiko Nishiyama (Bito)

Produced by: Satoshi Teshirogi (Dentsu West Japan Inc.)

Making Filming & Editing: Shoji Yasui, Koichi Susumu (Biyori)

Stills: Rihiro Ikeda (D-76)